Products Description

The body adopts the whole steel plate welding structure, and the tempering treatment by the large tempering furnace equipment caneliminate the deformation caused by welding stress and processing stress, and ensure the accuracy of the machine tool.

The main cylinder on both sides adopts imported electro-hydraulic single servo valve and grating ruler of Spanish FAGOR company to formclosed-loop control. The feedback is accurate and the slider is running accurately, thus the bending accuracy and the slider repeated positioning accuracy are high. The slider position feedback accuracy is high, the operation is accurate and stable, the synchronization performance is good, the bending accuracy is high, the slider repeated positioning accuracy is high. The rear stop adopts a more complete function of precision CNC rear stop mechanism. The hydraulic system adopts integrated control system, which reduces the installation of pipelines, overcomes the phenomenon of oil leakage, ensures the working stability of the machine tool,and the appearance is simple and beautiful.

The mechanical deflection automatic compensation mechanism eliminates the influence of the slider deformation on the quality of the workpiece, and the CNC system automatically adjusts the compensation amount, making the operation convenient and accurate. CNC system adopts Dutch Delem bending machine special CNC system.

Product Pictures

Product Details

★ Fast Clamp

The upper punch can be easily and conveniently attached and detached, significantly enhancing efficiency and streamlining the workflow.

| |

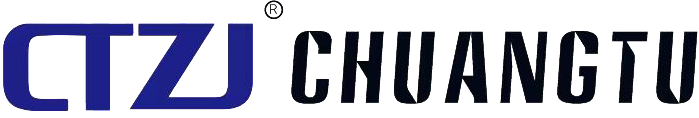

★ High Precision Stop Finger

The middle position uses two CNC stop finger, can be programmed to control the position, stop specified level, fast speed. | |

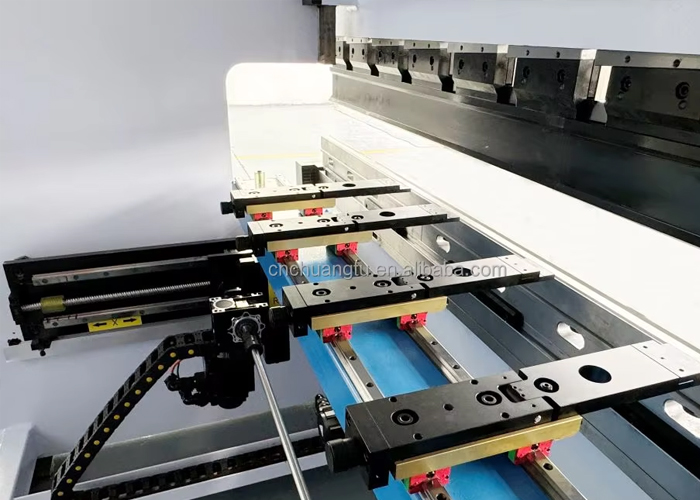

★ Mechanical Crowning (V-axis)

The mechanical deflection compensation with high CNC precision is adopted.Because of more compensation points, the bending machine can realize linear compensation when bending the workpiece in the work,which can improve the bending effect of the workpiece. It has the characteristics of free maintenance and more accurate compensation. | |

★ 4+1 Axis CNC Back Gauge X axis is driven by linear guide rail, ball screw and servo motor to ensure the accurate positioning of X axis. The R axis is driven by high-power servo motor, linear guide rail and ball screw, which has the characteristics of fast response and accurate positioning. | |

★ Delem DA-53T Control System

10.1 "high resolution true color TFT display; Up to 4 axes control (Y1,Y2 + 2 auxiliary axes); Deflection compensation control; Have mold/material/product library; Support servo or frequency conversion control; Advanced Y-axis control algorithm; Interworking between two Nodes (Optional); Profile-53TL Offline programming software. | |

Technical parameter

Specification | Nominal pressure (kN) | Length of working table (mm) | Distance between uprights (mm) | Throat depth (mm) | Ram stroke (mm) | Main motor power (Kw) |

| WC67Y40/2000 | 400 | 2000 | 1800 | 250 | 100 | 4 |

| WC67Y40/2200 | 400 | 2200 | 1800 | 250 | 100 | 4 |

| WC67Y40/2500 | 400 | 2500 | 2000 | 250 | 100 | 4 |

| WC67Y50/2500 | 500 | 2500 | 1900 | 250 | 100 | 4 |

| WC67Y50/3200 | 500 | 3200 | 2600 | 250 | 100 | 4 |

| WC67Y63/2500 | 630 | 2500 | 2020 | 250 | 120 | 5.5 |

| WC67Y63/3200 | 630 | 2500 | 2600 | 250 | 120 | 5.5 |

| WC67Y80/3200 | 800 | 3200 | 2600 | 250 | 120 | 5.5 |

| WC67Y80/4000 | 800 | 3200 | 3200 | 250 | 120 | 5.5 |

| WC67Y100/2500 | 1000 | 2500 | 2000 | 320 | 120 | 7.5 |

| WC67Y100/3200 | 1000 | 3200 | 2600 | 320 | 120 | 7.5 |

| WC67Y100/4000 | 1000 | 4000 | 3200 | 320 | 120 | 7.5 |

| WC67Y100/5000 | 1000 | 5000 | 4000 | 320 | 120 | 7.5 |

| WC67Y125/2500 | 1250 | 2500 | 2000 | 320 | 120 | 7.5 |

| WC67Y125/3200 | 1250 | 3200 | 2600 | 320 | 120 | 7.5 |

| WC67Y125/4000 | 1250 | 4000 | 3200 | 320 | 120 | 7.5 |

| WC67Y125/5000 | 1250 | 5000 | 4000 | 320 | 120 | 7.5 |

| WC67Y160/3200 | 1600 | 3200 | 2600 | 400 | 200 | 11 |

| WC67Y160/4000 | 1600 | 4000 | 3200 | 400 | 200 | 11 |

| WC67Y160/5000 | 1600 | 5000 | 4000 | 400 | 200 | 15 |

| WC67Y160/6000 | 1600 | 6000 | 4800 | 400 | 200 | 15 |

| WC67Y200/3200 | 2000 | 3200 | 2600 | 400 | 200 | 15 |

| WC67Y200/4000 | 2000 | 4000 | 3200 | 400 | 200 | 15 |

| WC67Y200/5000 | 2000 | 5000 | 4000 | 400 | 200 | 15 |

| WC67Y200/6000 | 2000 | 6000 | 4800 | 400 | 200 | 15 |

| WC67Y250/3200 | 2500 | 3200 | 2600 | 400 | 250 | 22 |

| WC67Y250/4000 | 2500 | 4000 | 3200 | 400 | 250 | 22 |

| WC67Y250/5000 | 2500 | 5000 | 4000 | 400 | 250 | 22 |

| WC67Y300/5000 | 3000 | 4000 | 3200 | 400 | 250 | 22 |

| WC67Y300/5000 | 3000 | 5000 | 4000 | 400 | 250 | 22 |

| WC67Y300/5000 | 3000 | 6000 | 4800 | 400 | 250 | 22 |

| WC67Y400/5000 | 4000 | 5000 | 4000 | 400 | 250 | 30 |

| WC67Y400/6000 | 4000 | 6000 | 4800 | 400 | 250 | 37 |

| WC67Y500/6000 | 5000 | 6000 | 4800 | 400 | 300 | 37 |

| WC67Y500/12000 | 5000 | 12000 | 多立柱 | 400 | 300 | 37 |

| WC67Y600/7000 | 6000 | 7000 | 5600 | 400 | 300 | 45 |

| WC67Y700/7000 | 7000 | 7000 | 5600 | 400 | 300 | 45 |

| WC67Y800/6000 | 8000 | 8000 | 5600 | 500 | 400 | 55 |

| WC67Y1000/6000 | 10000 | 6000 | 5600 | 600 | 500 | 75 |

Tags: