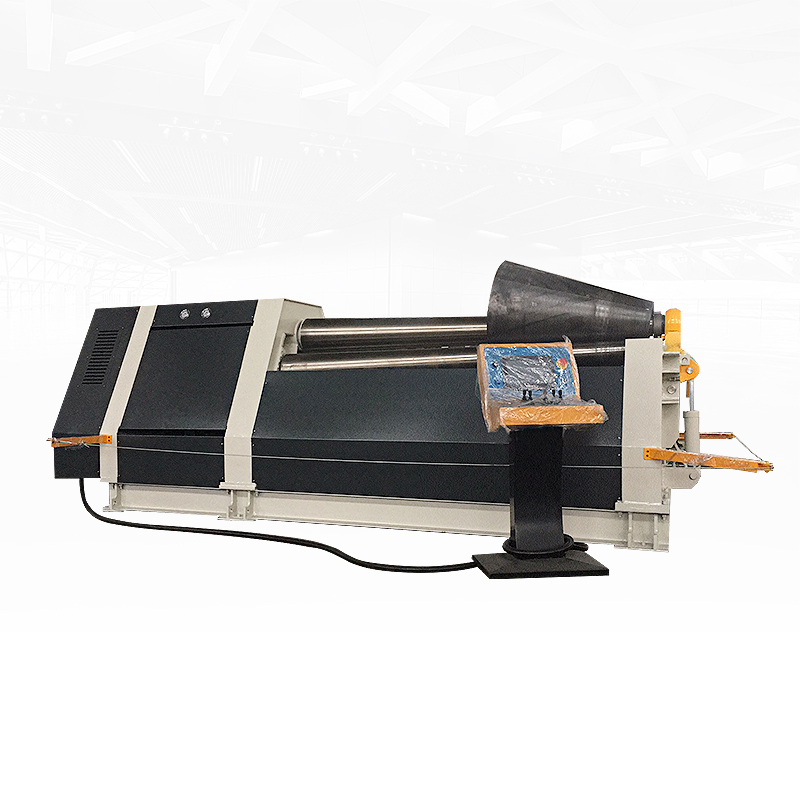

Products Description

The working principle of the cone plate rolling machine: the rod of the symmetrical cone plate rolling machine is in the symmetrical position of the center of the two rollers, and the hydraulic cylinder acts on the piston for vertical lifting movement, and the final gear of the main reducer drives the two roller gears to engage and rotate motion, providing torque for the winding plate. A plate rolling machine, the specification of flat plastic plate in the plate rolling machine three work rollers (two lower rollers. Between an upper roller), with the help of the pressure of the upper roller and the rotation of the lower roller, through multiple continuous bending (the inner layer compression deformation, the middle layer does not change, the outer layer tensile deformation), plastic deformation is generated, and the desired cone or cone is rolled. The machine adopts coil plate with thickness less than 20mm.

Product Pictures

The upper roller can be adjusted by mechanical or hydraulic pressure, which can be used for special winding conical products, making stainless steel cone, steel plate size head winding, small diameter cone, simple, convenient and fast. The product model can be customized according to the customer model. The machine is widely used in high precision requirements, such as: aviation, nuclear power and other metal structural parts manufacturing operations and chemical machinery, offshore oil platforms, oil, gas and water pipelines and other industries.

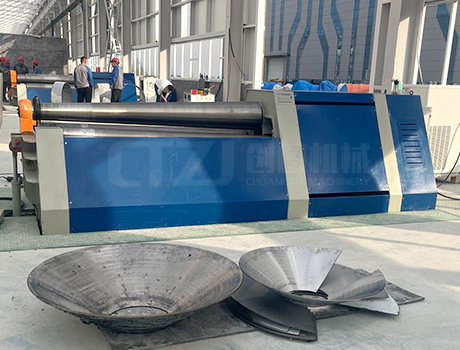

Product Cases

Technical parameter

Specification | Plate thickness (mm) | Plate Width (mm) | Dlameter of upper roll (mm) | Main motor power(kw ) | Dimensions (mm) |

| CTW12-4X1500 | 1-4 | 1500 | 140 | 3 | 2800x800x1000 |

| CTW12-4X2000 | 1-4 | 2000 | 160 | 4 | 3400x900x1000 |

| CTW12-6X2000 | 1-6 | 2000 | 170 | 4 | 3600x1100x1100 |

| CTW12-6X2500 | 1-6 | 2500 | 190 | 5.5 | 4000x1200x1200 |

| CTW12-8X2500 | 2-8 | 2500 | 220 | 7.5 | 4700x1500x1500 |

| CTW12-12X2000 | 3-12 | 2000 | 240 | 7.5 | 4200x1500x1500 |

| CTW12-12X2500 | 3-12 | 2500 | 260 | 11 | 4800x1600x1600 |

| CTW12-16X2500 | 3-16 | 2500 | 280 | 11 | 5000x1700x1700 |

| CTW12-16X4000 | 4-16 | 4000 | 370 | 22 | 6600x1700x1700 |

| CTW12-20X2500 | 3-20 | 2500 | 340 | 15 | 5000x1900x1880 |

| CTW12-20X3200 | 4-20 | 3200 | 380 | 18.5 | 4600x2200x2200 |

| CTW12-25X2000 | 3-25 | 2000 | 340 | 15 | 4600x1900x1900 |

| CTW12-25X2500 | 4-25 | 2500 | 380 | 18.5 | 5100x2200x2200 |

| CTW12-25X3200 | 5-25 | 3200 | 420 | 22 | 6600x2550x2500 |

| CTW12-30X2500 | 5-30 | 2500 | 420 | 22 | 6000x2800x2900 |

| CTW12-30X3200 | 5-30 | 3200 | 450 | 30 | 6800x2900x2900 |

| CTW12-40X2500 | 6-40 | 2500 | 520 | 37 | 6500x3000x3000 |

| CTW12-40X3200 | 6-40 | 3200 | 550 | 2x22 | 7100x3000x3000 |

| CTW12-50X2500 | 8-50 | 2500 | 580 | 2x22 | 6500x3000x3000 |

| CTW12-50X3200 | 8-50 | 3200 | 620 | 2x30 | 7100x3000x3000 |

| CTW12-60X3200 | 10-60 | 3200 | 660 | 2x37 | 7200x3300x3500 |

| CTW12-80X3200 | 16-80 | 3200 | 800 | 2x45 | 7500x3500x3800 |

| CTW12-100X3200 | 20-100 | 3200 | 860 | 2x55 | 8100x3800x3800 |

| CTW12-120X3200 | 20-120 | 3200 | 920 | 2x63 | 8200x4000x4000 |

| CTW12-150X3200 | 25-140 | 3200 | 1080 | 2x75 | 8600x5000x5000 |

| CTW12-160X3200 | 30-160 | 3200 | 1160 | 2x75 | 8600x5200x5200 |

| CTW12-180X3200 | 30-180 | 3200 | 1220 | 2x90 | 8800x6000x5800 |

Tags: plate rolling machine