Products Description

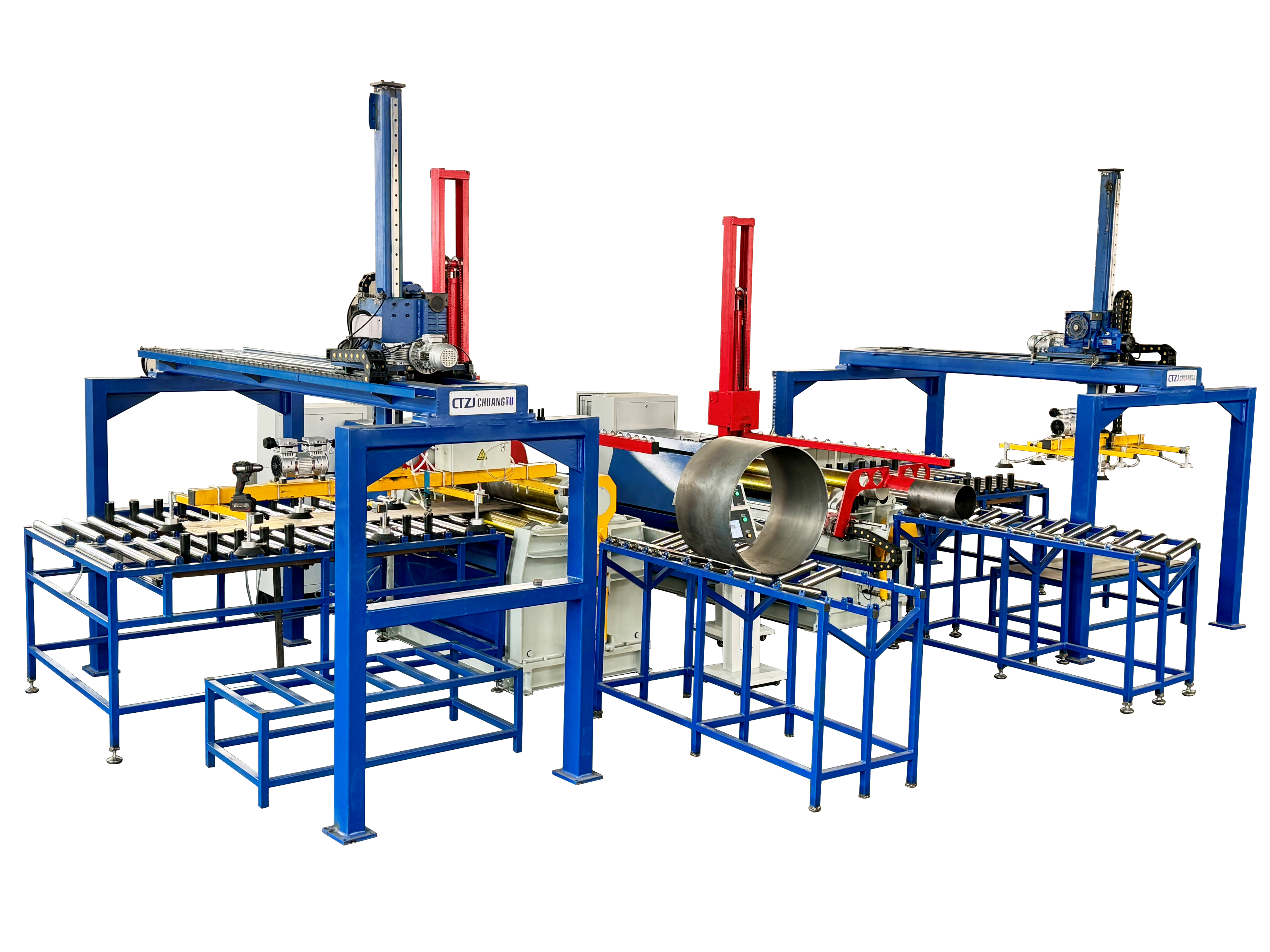

CHUANGTU rolling machine production line is the ideal equipment to increase production and automatic rolling, the R & D process of machinery can be configured according to the requirements of users, a variety of suitable automatic auxiliary devices, reduce the downtime of the rolling cycle and rolling process management personnel, improve production efficiency。

Product Pictures

Structural characteristics of the fully automatic four-roller rolling production line

The reclaiming platform is equipped with an automatic splitter, which can automatically separate the plates to prevent the plates from adsorbing each other and ensure that one plate is taken at a time.

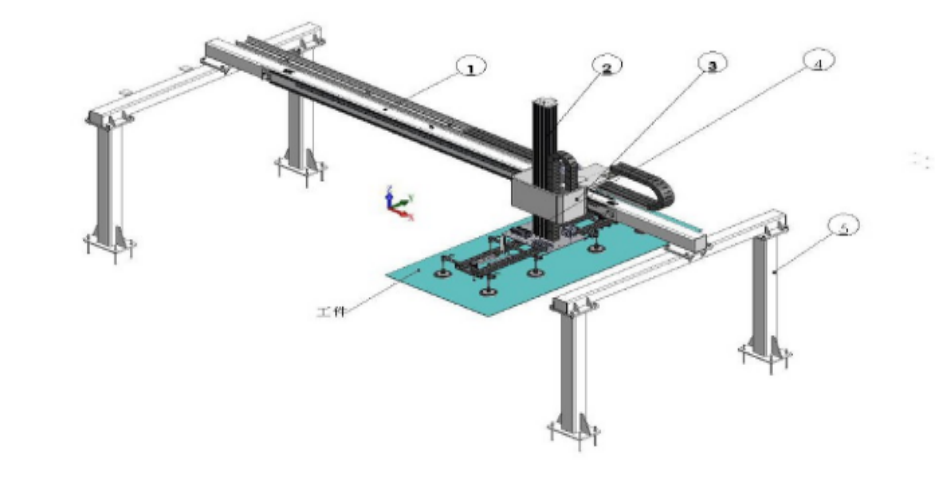

The automatic reclaiming device adopts a large suction vacuum suction cup with a buffer, which has a simple structure and a low failure rate. The suction cup guide column is buffered by a spring, and the air pipe is connected to the metal guide column, and the structure is stable and not easy to fall off. The adjustable suction cup bracket can adjust the position of the suction cup according to the length and width of the rolled workpiece to ensure the stability of the reclaiming. The lifting device is equipped with a stable guide rod to ensure fast and stable lifting and walking. Choose high-power cylinder or servo motor, which has fast lifting speed and stable operation.

The automatic alignment feeding device consists of an alignment device installed on the feeding platform and a feeding device. The alignment device adopts a double-sided adjustable alignment system and is equipped with multiple sets of rolling alignment wheels, which is suitable for the alignment of plates with large differences in plate width. When the feeding device pushes the sheet, the alignment device is always in the alignment state to correct the feeding direction of the sheet.

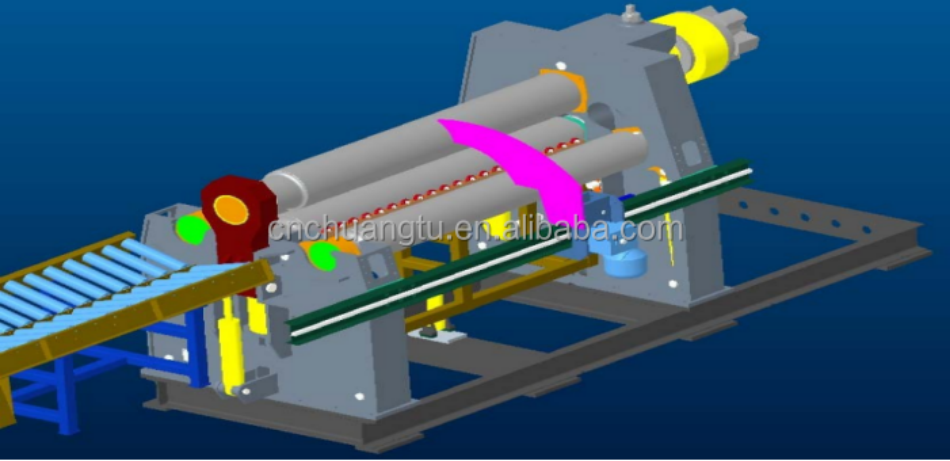

The host adopts an arc straight four-roller plate rolling machine, and the automatic mode is used when rolling. The parameters of the rolling circle are determined first, and the program of the CNC rolling country is formulated through these parameters. When controlled by numerical control, the mechanical properties of the plates are uniform, the same batch of products have good forming consistency, and the coiling efficiency is high. The sheet metal is loaded at one time, and the sheet storage section pre-bending and rolling forming can be completed without turning the head. Can roll cinnamon, oval, square and other workpieces.

After the automatic discharging device is completed, the rodless cylinder or servo motor will push the workpiece out, and the electric V-shaped transport frame will transport the workpiece to the next process.With the assistance of supporting manufacturers, uncoiling, leveling, and shearing production lines can be installed before the reclaiming process to realize automatic expansion before coiling. A welding operation machine, automatic welding production line and flexible stacking device are installed behind the electric V-shaped conveying rack to realize the extension of the automatic rolling process.

Performance Characteristics

Meet the thickness of 2mm-50mm, the maximum width is 3000mm, and all kinds of metal sheets are rolled into a circle at one time touch screen control, one-key operation, easy operation.high consistency of rolling roundness,use EPS to automatically level the four-roller shaft to ensure the same diameter on both sides of the round pass pneumatic tipping, pneumatic discharging, fast speed, single machine daily output can reach 160-400 pieces high rolling precision, no obvious remaining straight edges on the seams, no need for follow-up rounding.

Technical parameter

Model | Max rolling thickness/length | Diameter of Main Roller | Diameter of Side Roller | Rolling Speed | Main Motor |

mm | mm | mm | m/min | KW | |

W12-4x1500 | 4x1500 | 140 | 120 | 4 | 2.2 |

W12-4x2000 | 4x2000 | 160 | 140 | 4 | 2.2 |

W12-4x2500 | 4x2500 | 190 | 150 | 4 | 3 |

W12-4x3000 | 4x3000 | 210 | 170 | 4 | 7.5 |

W12-4x4000 | 4x4000 | 270 | 210 | 4 | 5.5 |

W12-6x2000 | 6x2000 | 190 | 150 | 4 | 5.5 |

W12-6x2500 | 6x2500 | 210 | 170 | 4 | 7.5 |

W12-8x1500 | 8x1500 | 200 | 170 | 4 | 5.5 |

W12-8x2000 | 8x2000 | 210 | 180 | 4 | 7.5 |

W12-10X2000 | 10x2000 | 230 | 180 | 4 | 7.5 |

W12-10X2500 | 10x2500 | 270 | 210 | 4 | 11 |

W12-12x2000 | 12x2000 | 245 | 200 | 4 | 11 |

W12-12x2500 | 12x2500 | 265 | 220 | 4 | 11 |

W12-16x2000 | 16x2000 | 250 | 210 | 4 | 15 |

W12-16x2500 | 16x2500 | 300 | 240 | 4 | 15 |

W12-20x2000 | 20x2000 | 300 | 250 | 4 | 18.5 |

W12-20x2500 | 20x2500 | 350 | 280 | 4 | 18.5 |

W12-25X2000 | 25x2000 | 360 | 250 | 4 | 15 |

W12-25X2500 | 25x2500 | 390 | 300 | 4 | 18.5 |

W12-30x2500 | 30x2500 | 410 | 340 | 4 | 22 |

W12-30x3000 | 30x3000 | 450 | 380 | 4 | 30 |

W12-35x2000 | 35x2000 | 430 | 330 | 4 | 30 |

W12-35x2500 | 35x2500 | 460 | 360 | 4 | 30 |

W12-40x2500 | 40x2500 | 500 | 420 | 4 | 37 |

W12-40x3000 | 40x3000 | 540 | 440 | 4 | 45 |

W12-45x2500 | 45x2500 | 460 | 420 | 4 | 30 |

W12-45x3000 | 45x3000 | 510 | 460 | 4 | 37 |

W12-50x2500 | 50x2500 | 560 | 450 | 4 | 45 |

W12-50x3000 | 50x3000 | 600 | 480 | 4 | 55 |

W12-60x2500 | 60x2500 | 610 | 500 | 4 | 55 |

W12-60x3000 | 60x3000 | 650 | 520 | 4 | 75 |

W12-65x3000 | 65x3000 | 650 | 550 | 4 | 55 |

W12-85x3000 | 85x3000 | 760 | 680 | 4 | 75 |

Tags: