Products Description

Our advanced 4-roll plate rolling machine enables bending on both sides without the need for return.

The PLC system allows for full automatic control, eliminating the requirement of additional processing steps for end bending. Quality certificates such as CE and ISO9001 are provided.

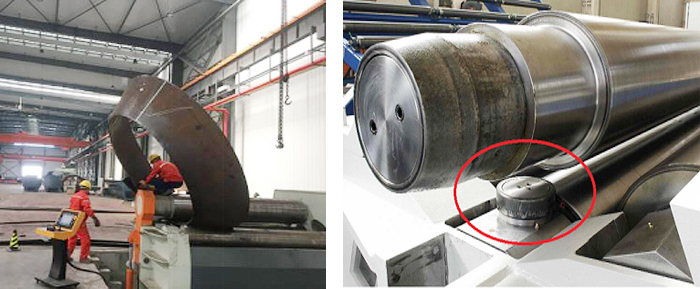

Product picture

Technological Advantages

* Effortless operation with a diverse range of bending shapes.

* Equipped with CNC control and digital readout for precise positioning of each roller, ensuring high accuracy.

* Full hydraulic drive system ensures high efficiency and energy savings.

* Productivity is increased by 50%-80% compared to traditional 3-roller plate rolling machines.

* Material alignment is convenient and accurate, preventing misalignment issues.

* Cone bending device features permanent lubrication for smooth operation.

* Non-slip rolling guarantees safety during the process.

* Surplus flat edge is minimized compared to other plate rolling machines when pre-bending.

Product picture

Product Details

★ Hardened Rolls

The highly durable carbon steel (C45) rolls are precisely machined by CNC lathes, ensuring high precision without causing anynotching effects. The working surfaces of the rolls undergo induction harden ing to achieve a hardness level of HRC 48-52.

| |

★ Hydraulic Pump Station The hydraulic system is made strictly according to the national and industrial standards.The factors of energy saving and power consumption have been considered. The connection point adopts the professional sealing glue and the leakage can be well prevented, also the repair and maintenance is quite convenient. | |

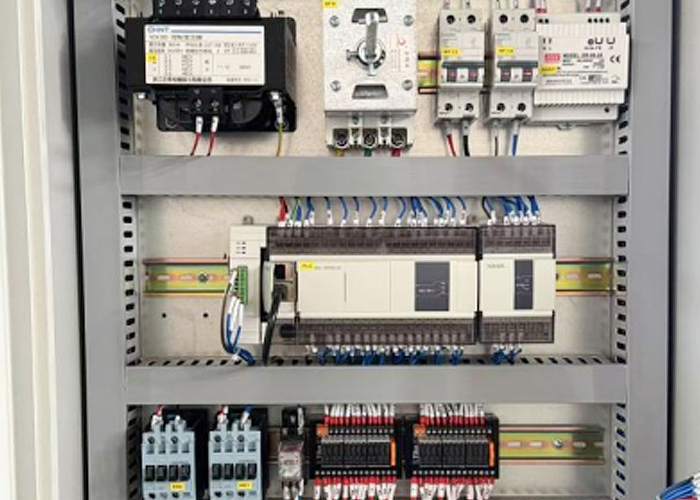

★ PLC (Siemens) The machine's bottom and lateral rolls are synchronized through a PLC control system. | |

★ Upper and lower roller drive The double roll drive completely avoids slipping during the pre-bending process. Fully driven upper and lower rolls on both sides of the sheet ensure precise feed control, and synchronized movement ensures reliable and stable feeding. | |

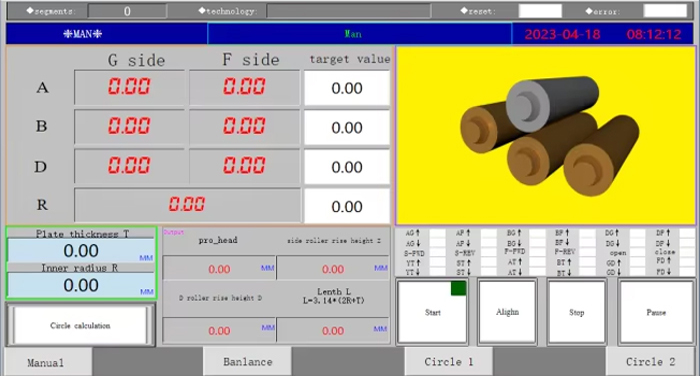

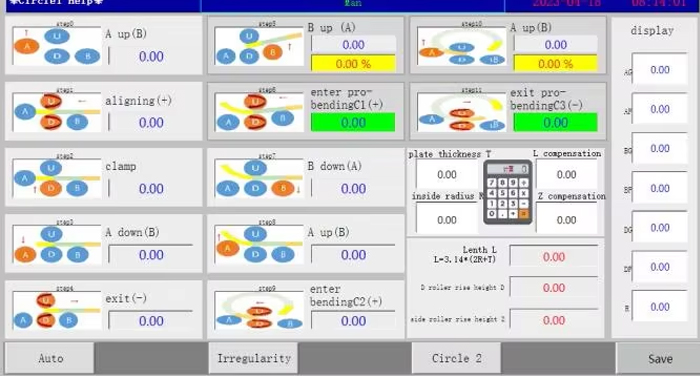

CNC Control System

The ten-inch large screen system with automatic calculation function and automatic generation of the rolled round process,equipped with a special independent operation panel and remote troubleshooting function, can realize one-button operation,providing powerful data storage and recall function.

Optional Equipment Parts

Side Brackets Avoids collapsing or reopening when rolling thin sheets; Uniform self-calibration and support of the sheet when rolling conical and cylindrical cylinders; Precise hydraulic movement; Ability to support the rolled sheet to maintain the desired curvature. Fitted with rollers to support inclined sheets to maintain the cone shape of the sheet. |  |

Hydraulic vertical support Supports workpieces with large diameters when rolling thin plates,preventing collapse or overlap; Precise hydraulic movement, overload protection; Can be used to correct sheet edges for spot welding; Maximum support diameter 4000mm; Self-steering rollers (for supporting inclined conical sheets), which support the sheet to maintain the correct diameter throughout the winding period, without the need for rollers. |  |

Conical bending device Coning device is mainly composed of guide wheel, pin shaft, composite bearing, gland and so on. Its role is mainly to guide the line position when the cone is rolled, which is convenient to roll the small taper cylinder, the operator is simple and the use is reliable. |  |

Technical parameter

Specification | Plate thickness (mm) | Plate width (mm) | Dlameter of upper roll(mm) | motor power (kw ) | Dimensions (mm) |

| CTW12-4X1500 | 1-4 | 1500 | 140 | 3 | 2800x800x1000 |

| CTW12-4X2000 | 1-4 | 2000 | 160 | 4 | 3400x900x1000 |

| CTW12-6X2000 | 1-6 | 2000 | 170 | 4 | 3600x1100x1100 |

| CTW12-6X2500 | 1-6 | 2500 | 190 | 5.5 | 4000x1200x1200 |

| CTW12-8X2500 | 2-8 | 2500 | 220 | 7.5 | 4700x1500x1500 |

| CTW12-12X2000 | 3-12 | 2000 | 240 | 7.5 | 4200x1500x1500 |

| CTW12-12X2500 | 3-12 | 2500 | 260 | 11 | 4800x1600x1600 |

| CTW12-16X2500 | 3-16 | 2500 | 280 | 11 | 5000x1700x1700 |

| CTW12-16X4000 | 4-16 | 4000 | 370 | 22 | 6600x1700x1700 |

| CTW12-20X2500 | 3-20 | 2500 | 340 | 15 | 5000x1900x1880 |

| CTW12-20X3200 | 4-20 | 3200 | 380 | 18.5 | 4600x2200x2200 |

| CTW12-25X2000 | 3-25 | 2000 | 340 | 15 | 4600x1900x1900 |

| CTW12-25X2500 | 4-25 | 2500 | 380 | 18.5 | 5100x2200x2200 |

| CTW12-25X3200 | 5-25 | 3200 | 420 | 22 | 6600x2550x2500 |

| CTW12-30X2500 | 5-30 | 2500 | 420 | 22 | 6000x2800x2900 |

| CTW12-30X3200 | 5-30 | 3200 | 450 | 30 | 6800x2900x2900 |

| CTW12-40X2500 | 6-40 | 2500 | 520 | 37 | 6500x3000x3000 |

| CTW12-40X3200 | 6-40 | 3200 | 550 | 2x22 | 7100x3000x3000 |

| CTW12-50X2500 | 8-50 | 2500 | 580 | 2x22 | 6500x3000x3000 |

| CTW12-50X3200 | 8-50 | 3200 | 620 | 2x30 | 7100x3000x3000 |

| CTW12-60X3200 | 10-60 | 3200 | 660 | 2x37 | 7200x3300x3500 |

| CTW12-80X3200 | 16-80 | 3200 | 800 | 2x45 | 7500x3500x3800 |

| CTW12-100X3200 | 20-100 | 3200 | 860 | 2x55 | 8100x3800x3800 |

| CTW12-120X3200 | 20-120 | 3200 | 920 | 2x63 | 8200x4000x4000 |

| CTW12-150X3200 | 25-140 | 3200 | 1080 | 2x75 | 8600x5000x5000 |

| CTW12-160X3200 | 30-160 | 3200 | 1160 | 2x75 | 8600x5200x5200 |

| CTW12-180X3200 | 30-180 | 3200 | 1220 | 2x90 | 8800x6000x5800 |

Tags: plate rolling machine small four-roller plate rolling machine