Products Description

QC12Y/K NC hydraulic swing beam shearing machine with E21S has an all-steel welded structure and comprehensive treatment (vibration ageing, heat treatment) to remove internal stresses, resulting in excellent rigidity and stability. Precision sliding guides are used to eliminate guide gaps, resulting in high shearing quality. The E21S system is easy to operate.

Product Pictures

Numerical Control System

|

|

|

E21S (ESTUN)Standard | DAC-360T (Delem) Optional | CybTouch 8G(CYBELEC) Optional |

. Back gauge(X axis ) movement control . Control AC motor or inverter . Intelligent and unilateral positioning . Work-piece counting function . Double programmable digital output . 40 programs stored, 25 steps per program . One key back-up/restore of parameters . Unit for mm/inch . Language for Chinese/English . Cutting angle adjustment | . Panel based housing . Bright LCD . screen Back / front gauge control . Retract function . Cutting angle and gap control . Stroke length limitation . Manual movement of all axes . Force control . Sheet thickness measurement . Return to Sender function . Sheet support | . High-contrast touchscreen, with vivid colors . Simple pages, large keys, clear display . Intuitive and user-friendly interface . Complete programming of parts in seconds . Quick set up of the machine with Cut page |

Product Details

★ Main Motor German famous brand motor improves the lifespan of the machine and keeps the machine working in low noise environment. | |

★ HIWIN Ball Screw Adjust Back gauge Up and Down

| |

★ Feeding Table Roller ball is installed on the arm with ruler can reduce the abrasion and feeder the machine easily and accurately. | |

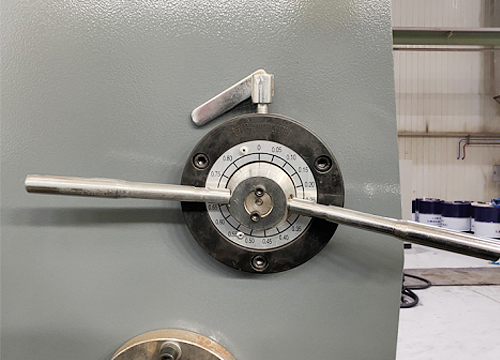

★ Blade Clearance Adjustment Adjust the cutting blades gap by motor according the cutting thickness of the metal sheet can get better cutting performance. | |

Technical parameter

Specification | Shearing thickness (mm) | Shearing width (mm) | Shearing nge (°) | Strokes (mm) | Backgauge range (mm) | motor power (Kw) |

| QC12Y-4X2500 | 4 | 2500 | 1°30' | 18 | 20~600 | 4.0 |

| QC12Y-4X3200 | 4 | 3200 | 1°30' | 18 | 20~600 | 5.5 |

| QC12Y-4X4000 | 4 | 4000 | 1°30' | 12 | 20~600 | 5.5 |

| QC12Y-4X5000 | 4 | 5000 | 1°30' | 10 | 20~600 | 5.5 |

| QC12Y-4X6000 | 4 | 6000 | 1°30' | 7 | 20~800 | 7.5 |

| QC12Y-6X2500 | 6 | 2500 | 1°30' | 18 | 20~600 | 7.5 |

| QC12Y-6X3200 | 6 | 3200 | 1°30' | 14 | 20~600 | 7.5 |

| QC12Y-6X4000 | 6 | 4000 | 1°30' | 12 | 20~600 | 7.5 |

| QC12Y-6X5000 | 6 | 5000 | 1°30' | 10 | 20~600 | 7.5 |

| QC12Y-6X6000 | 6 | 6000 | 1°30' | 7 | 20~800 | 7.5 |

| QC12Y-8X2500 | 8 | 2500 | 1°30' | 14 | 20~600 | 7.5 |

| QC12Y-8X3200 | 8 | 3200 | 1°30' | 10 | 20~600 | 7.5 |

| QC12Y-8X4000 | 8 | 4000 | 1°30' | 8 | 20~600 | 11 |

| QC12Y-8X5000 | 8 | 5000 | 1°30' | 7 | 20~800 | 15 |

| QC12Y-8X6000 | 8 | 6000 | 1°30' | 5 | 20~800 | 15 |

| QC12Y-8X8000 | 8 | 8000 | 1°30' | 5 | 20~800 | 15 |

| QC12Y-10X2000 | 10 | 2000 | 1°30' | 12 | 20~600 | 11 |

| QC12Y-10X2500 | 10 | 2500 | 1°30' | 10 | 20~600 | 11 |

| QC12Y-10X3200 | 10 | 3200 | 1°30' | 10 | 20~600 | 11 |

| QC12Y-10X4000 | 10 | 4000 | 1°30' | 8 | 20~600 | 15 |

| QC12Y-12X2000 | 12 | 2000 | 2° | 12 | 20~600 | 15 |

| QC12Y-12X2500 | 12 | 2500 | 2° | 10 | 20~600 | 15 |

| QC12Y-12X3200 | 12 | 3200 | 2° | 9 | 20~600 | 15 |

| QC12Y-12X4000 | 12 | 4000 | 2° | 8 | 20~800 | 18.5 |

| QC12Y-12X5000 | 12 | 5000 | 2° | 7 | 20~800 | 22 |

| QC12Y-12X6000 | 12 | 6000 | 2° | 6 | 20~800 | 22 |

| QC12Y-12X8000 | 12 | 8000 | 2° | 5 | 20~800 | 22 |

| QC12Y-16X2500 | 12 | 2500 | 2° | 8 | 20~600 | 18.5 |

| QC12Y-16X3200 | 12 | 3200 | 2° | 7 | 20~600 | 18.5 |

| QC12Y-16X4000 | 12 | 4000 | 2° | 5 | 20~600 | 18.5 |

| QC12Y-20X2000 | 12 | 2000 | 2°30' | 8 | 20~800 | 22 |

| QC12Y-20X2500 | 12 | 2500 | 2°30' | 6 | 20~800 | 22 |

| QC12Y-20X3200 | 12 | 3200 | 2°30' | 6 | 20~1000 | 30 |

| QC12Y-20X4000 | 12 | 4000 | 2°30' | 6 | 20~1000 | 30 |

| QC12Y-25X2000 | 12 | 2000 | 3° | 6 | 20~1000 | 30 |

| QC12Y-25X2500 | 12 | 2500 | 3° | 6 | 20~1000 | 30 |

| QC12Y-25X3200 | 12 | 3200 | 3° | 6 | 20~1000 | 37 |

| QC12Y-30X2500 | 12 | 2500 | 3°30' | 6 | 20~1000 | 37 |

| QC12Y-30X3200 | 12 | 3200 | 3°30' | 5 | 20~1000 | 45 |

| QC12Y-40X2500 | 12 | 2500 | 4° | 5 | 30~1000 | 55 |

| QC12Y-40X3200 | 12 | 3200 | 4° | 5 | 20~1000 | 55 |

| QC12Y-50X3000 | 50 | 3000 | 3° | 5 | - | 90x3 |

| QC12Y-50X6000 | 50 | 6000 | 3° | 5 | - | 90x5 |

| QC12Y-60X3500 | 60 | 3500 | 3°30' | 5 | - | 90x4 |

Tags: